黑土耕地不仅数量逐渐减少,而且质量也逐渐下降。黑土耕地质量下降的主要表现是:一方面耕层结构变差,耕作层变薄,犁底层变得浅、厚、硬,亚表层过于紧实;另一方面,耕层,尤其是亚表层土壤有机质含量降低,土壤肥力下降(犁底层和亚表层的概念见图 1)。土壤肥力下降原因主要有以下几方面:一是有机肥料施用量低,秸秆还田量不足;二是种植结构不合理,玉米连作现象普遍;三是不合理的耕作造成土壤物理性状退化[1]。如何提升黑土耕地的土壤质量?理论上,要求合理耕作的同时,还能补充土壤有机质,最终形成深厚、肥沃、健康的表土层(耕作层和亚表层)。实现上述目标的最重要技术手段之一,是机械化深松与秸秆还田结合,以便快速培肥有机质缺乏、土体上下水气不畅的土壤耕作层和亚表层[2]。

|

图 1 土壤亚表层的概念 Fig. 1 Concept of subsoil layer |

在我国,现行的秸秆还田主要有三种模式:一是浅旋,二是地表覆盖,三是翻压。采用这些模式进行秸秆还田虽然有一定的效果,但其推广比较困难,主要原因除了需要大型机具,土壤还需要轮作,甚至休耕。除此共性困难之外,浅旋一般会引起土壤大空隙过多(熟称“种地漏风”);覆盖在一些地区会导致地温降低、病虫害增多,且由于无法打破犁底层,对提升整个土层(尤其是亚表层)土壤有机质含量作用有限,覆盖的CO2气体排放(“冒气”)与焚烧CO2气体排放(“冒烟”)在温室气体贡献方面没有本质区别;翻压处理费工、土层颠倒,有些地区会引起减产,第二年难以连续还田操作,再翻地时没有完全分解的秸秆又会被翻上来。

我国现阶段推广秸秆还田,应遵循以下原则:(1)解决土壤有机质最饥饿的关键土层—亚表层培肥需求;(2)尽可能多地将秸秆转化为土壤有机质,尤其是腐殖物质(HS),而不是都分解掉;(3)不影响来年种植;(4)能够连年还田;(5)保证耕作后土层顺序不颠倒;(6)适应已有的机具和宽窄行免耕播种成熟技术。按照上述需求,急需提出新的秸秆还田与耕作相结合工程技术,秸秆“富集深还”新模式及相应的工程技术在此背景下提出[1-3]。

1 秸秆富集深还与土壤亚表层培肥的概念秸秆富集深还:是将秸秆资源化与土壤培肥结合,深松与秸秆还田结合,秸秆还田与免耕播种结合,将玉米联合收割机(即“玉米收”)抛洒在地表的秸秆,通过机械化手段大比例(4:1~8:1)富集到预定的条带并施入土壤亚表层,同时能种还分离适应免耕播种的新模式。

土壤亚表层:土壤亚表层是指20~40 cm深土体,一般包括犁底层和心土层的上部分[4],与植物生长和土壤固碳关系密切(见图 1)。

东北黑土区几十年的小四轮耕作模式,使犁底层变得浅、厚、硬,亚表层过于紧实,上下水气不通,相当于有效土层变薄,制约土壤肥力发挥。因此,以打破犁底层和增加有机质为特征“亚表层培肥”工程应尽快提上日程。

秸秆富集深还的优点:(1)土层顺序不变;(2)宽窄行种还分离,即当年埋秸秆的条带为宽行,不播种,不减密度;(3)免耕播种,即直接用免耕播种机在非埋秸秆条带播种;(4)条带状轮耕种植,每年埋秸秆的条带依次轮换,周期为4~8年任选,可连年全量深埋秸秆;(5)土壤搅动作业面积只有1/4或1/8,节省动力;(6)由于本技术属于种还分离,不需配施多余的氮肥和秸秆降解菌剂,并逐渐节约化肥,节省生产成本;(7)由于深埋,对土壤打破犁底层、实现亚表层培肥效果极好,并可以取代免耕的周期性深松。

2 秸秆富集深还机具研制第一代秸秆深还机具,是由秸秆深还开沟犁、双筒直排式秸秆还田机和秸秆深埋还田覆土施肥联合作业机组成(图 2),简称为“三件套”[5-6]。经过三次连续作业,可将秸秆粉碎埋入土壤亚表层,并形成玉米大垄双行的种植基础;但是需要三套设备和三次作业,较为麻烦。

|

图 2 第一代秸秆深还机具——“三件套” Fig. 2 The first generation of corn stalk deep incorporator—A three-piece set |

第二代秸秆深还机具,是“一种聚翻组合式秸秆深还机”[7],一次性将秸秆埋入土壤亚表层(图 3),优点是作业简单,一次性完成;缺点是属于翻压性质,土层顺序颠倒。

|

图 3 第二代秸秆深还机具——“三合一”一体机 Fig. 3 The second generation of corn stalk deep incorporator — Three-in-one |

第三代秸秆深还机具,“一种风力注入秸秆深还筒式犁”[8],可以将秸秆粉碎风力送入绞龙直接注入到土壤亚表层,还田效果十分理想,实现了一次性作业完成大比例秸秆富集深埋还田的重任(图 4)。

|

图 4 第三代秸秆深还机具——风力注入筒式犁 Fig. 4 The third generation of corn stalk deep incorporator—Wind-driven input cylinder plough |

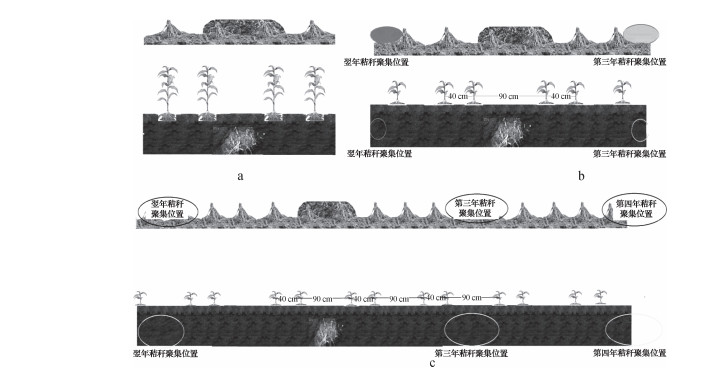

秸秆富集深还,可与目前主流的多种栽培耕作技术搭配,例如宽窄种植、大垄双行种植、免耕种植等,秸秆富集比例因实际的需要或秸秆环境压力自由选择。可以是4行一带(4:1富集,图 5a)、6行一带(6:1富集,图 5b)或8行一带(8:1富集,图 5c)。

|

注:a、b和c分别为4:1、6:1和8:1富集 Note:a、b and c stands for corn stalk enrichment ratio of 4:1、6:1 and 8:1, respectively 图 5 秸秆富集深还比例 Fig. 5 Corn stalk enrichment ratio of the deep incorporation |

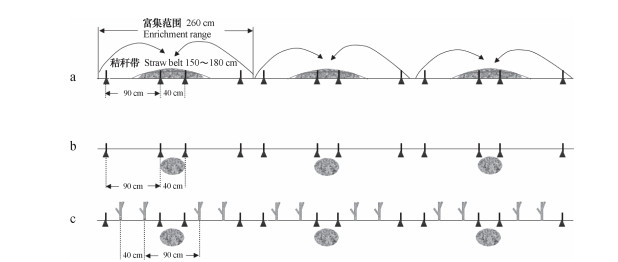

确定秸秆归行的富集幅宽及秸秆中聚带宽,用风力注入筒式犁将秸秆粉碎入土、带状免耕播(见图 6),具体步骤如下:

|

注:a为秸秆富集幅宽和归行宽度;b为粉碎入土;c为带状免耕播种 Note: a stands for straw enrichment range and belt width; b for incorporation of crushed straw into soil; c for no–till band seeding 图 6 玉米秸秆富集深埋还田方法(以四垄一带为例)[21] Fig. 6 Corn stalk enriching deep incorporation in to subsoil (Over a four-ridge wide row)[21] |

步骤一:秸秆富集幅宽的确定。在玉米种植集中连片且适于机械化的区域,根据不同的种植模式,收获机械类型以及经营者的种植规模确定秸秆富集的幅宽。一般而言,秸秆富集幅宽为4~8垄(2.6~5.2 m)。

步骤二:中聚成带。采用指盘搂草机将玉米收割机打碎落地的秸秆中聚成带,带宽1.5~1.8 m。

步骤三:粉碎入土。采用风力注入筒式犁通过三个环节将粉碎秸秆集中注入土壤亚表层。首先用碎杆刀轴将集聚的秸秆打碎抛入绞龙,通过绞龙输送至风机,再经风机将碎秸秆送入管式开掘体(筒式犁)继而落入土中。秸秆入土最大深度为35~40 cm,覆盖秸秆的覆土厚度为10~15 cm。

步骤四:带状免耕播种。富集的秸秆注入土壤深层后,以深埋秸秆的垄为中心,两侧相邻的垄均实施免耕种植,即以深埋秸秆的垄为中心留出空带,带宽90 cm,空带两侧各种植2行玉米,行距为40 cm。

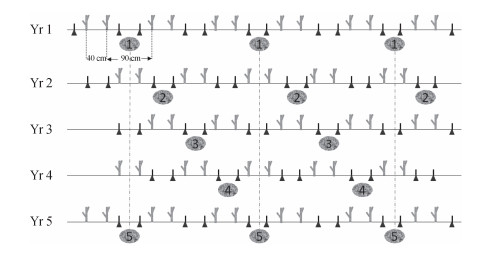

3.3 秸秆富集深还的年际循环由于秸秆富集深还的独到之处是多垄归为一垄,故每年产生的秸秆可以依次逐年持续条带深埋还田。其深还位置与最初深还位置重合为一个循环周期,四垄富集深还的循环周期为4年。如果苗带和埋秸秆带每年都换位,按条带依次逐年富集深还的年际循环见图 7。

|

注:Yr1-Yr5分别代表第一到第五年 Note:Yr1-Yr5 means the period from the 1st year to the 5th year 图 7 秸秆富集深还年际循环位置(每年苗带换位)[21] Fig. 7 Rotation of the four-ridge straw deep incorporation row with the seedling belt every year |

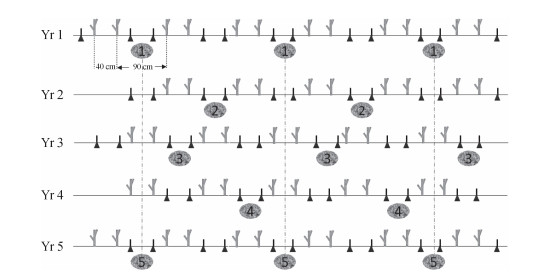

图 8为苗带和埋秸秆带每2年换一次位置,要求垄侧播种。无论是苗带和埋秸秆带每年都换位,还是每2年换一次位置,都适用于宽窄行种植模式,都适合与免耕播种。

|

注:Yr1-Yr5分别代表第一到第五年 Note: Yr1-Yr5 means the period from the 1st year to the 5th year 图 8 秸秆富集深还年际循环位置(每2年苗带换位)[21] Fig. 8 Rotation of the four-ridge straw deep incorporation row with the the seedling belt every other year |

增加耕层厚度和土壤有机质含量是提高地力的关键,2015—2016年农业部给东北10个亿资金用于黑土地保护试点,目标就两点:增加土壤有机质含量;耕作层厚度增加10 cm。秸秆富集深还可同时、快速地达到这两点。秸秆深还的改土效果很明显,一般土壤容重、水分和结构状况等物理性质有所改善[11-15]。秸秆富集深还可促使土壤亚表层有机碳含量增加10%~15%,土壤耕层由约15 cm增加至30 cm[11]。如果还沿用覆盖或浅施,由于不能打破犁底层,耕作层厚度增加10 cm就无法实现。

通常认为秸秆深埋还田可能分解缓慢,影响第二年播种。但模拟埋置试验中,秸秆还田120 d时,其分解率就达到60以上,330 d时超过65% [10]。对于秸秆深埋还田是否会引起第二年玉米产量降低也常存在疑虑,但在榆树黑土区玉米产量可以达到10 t以上,较传统耕作高5%[1]。辽宁省的试验也表明,秸秆深还对玉米产量没有不良影响[16-17]。

秸秆深埋还田能增加土壤胡敏酸、富里酸和胡敏素的数量,改善腐殖质组成,PQ从53%增加至63%,胡敏酸的H/C摩尔比从0.977提高至1.269 [18],促使黑土胡敏酸结构简单化和年轻化[18-20]。

由于秸秆富集深还技术属于种还分离栽培耕作模式,当季基本不存在秸秆分解与作物争氮的问题,可以少配或不配施多余的氮肥,一切与正常免耕播种栽培管理一致,不增加生产成本;由于秸秆埋在土壤深部,不影响第二年春天播种,到第二年秋天秸秆腐烂,成为优质的肥料,所以一般不需要特殊加施秸秆腐熟剂或其他菌剂,不增加还田成本,且第二年以后可节约一定数量的化肥。

机具油耗受多种因素影响,包括使用的拖拉机性能、机手的业务水平、地块形状、土壤阻力等因素。但总体而言,由于富集深还属于以免耕为主的技术,土壤搅动作业面积只有1/4~1/8,故节省动力。以吉林省榆树市恩育乡试验地为例,使用雷沃1204拖拉机,每日作业10 h,按纯作业效率为74%计算[9],按4:1富集秸秆,每小时可埋秸秆0.5 hm2,每公顷消耗零号柴油45 L。加上秸秆富集使用21~40 kW拖拉机带动指盘式搂草机,每公顷耗油约6~10 L,两项合计耗油约为每公顷最多55 L。按每升零号柴油6.5元计算,每公顷动力消耗成本约为358元,折合每亩24元(每公顷36元)。

秸秆富集深还操作比较简单,可因地制宜的选用。秸秆富集深还技术模式适用于玉米秸秆露天焚烧压力比较大、连年需要全量还田并且没有条件休耕的地区以及土壤耕作层尤其是亚表层急需培肥的耕地,一般东北平原、台地的黑土地区域,土体厚度在35 cm以上均可以应用。由于是四分之一到八分之一耕作,加之不用预先打碎秸秆和还田后耙地、镇压等工序,秸秆富集深还较一般的翻压、旋耕还田节省动力成本,经济效益和生态环境效益俱佳。

5 结论与展望秸秆富集深埋还田(富集深还)是一种基于土壤亚表层快速培肥理念,以筒式犁为主要机具,以条带轮耕作为主要特征,通过粉碎与风力注入将秸秆深埋于土壤亚表层的秸秆还田新技术,理念新颖,技术可行,适用于旱田作物,尤其是玉米宽窄行种植的秸秆还田,对土壤尤其是亚表层有很好的培肥效果。将有助于彻底解决秸秆还田成本高或效果差的瓶颈问题,为旱田秸秆田间处理与深厚肥沃耕层构建提供切实可行的机械化工程手段。

但秸秆富集深还毕竟是新生事物,急需宣传、引导、培训,急需扩大机具生产规模;同时需要研究不同地区、不同栽培模式下的工程技术参数,优化田间操作工艺、方法,为大面积推广应用做好准备。

| [1] |

窦森. 黑土地保护与秸秆富集深还. 吉林农业大学学报, 2016, 38(5): 511-516. Dou S. Black earth conservation and corn stover deep incorporation to subsoil (In Chinese). Journal of Jilin Agricultural University, 2016, 38(5): 511-516. (  0) 0) |

| [2] |

窦森, 陈光, 关松, 等. 秸秆焚烧的原因与秸秆深还技术模式研究. 吉林农业大学学报, 2017, 39(2): 127-133. Dou S, Chen G, Guan S, et al. Reasons for corn stover burning in fields and technical models for its deep incorporation to subsoil (In Chinese). Journal of Jilin Agricultural University, 2017, 39(2): 127-133. (  0) 0) |

| [3] |

窦森. 秸秆"富集深还"与土壤亚表层培肥. 植物营养与肥料学报, 2017, 23(6): 1670-1675. Dou S. Improving subsoil fertility through a new technology of continuous in belt and deep incorporation of corn stover (In Chinese). Journal of Plant Nutrition and Fertilizer, 2017, 23(6): 1670-1675. (  0) 0) |

| [4] |

窦森, 董雪, 董丽娟, 等. 松辽平原表土剥离技术体系--以松原市为例. 吉林农业大学学报, 2014, 36(2): 127-133. Dou S, Dong X, Dong L J, et al. Technical system of topsoil stripping of Songliao plain-Taking Songyuan as an example (In Chinese). Journal of Jilin Agricultural University, 2014, 36(2): 127-133. (  0) 0) |

| [5] |

窦森, 白洪波, 林长年, 等.双筒直排式秸秆还田机(发明专利, ZL 201610181128. 1). 2017-08-04 Dou S, Bai H B, Lin C N, et al. A machine with double tubes for return corn stover directly to field(Patent, ZL 201610181128. 1). 2017-08-04 (  0) 0) |

| [6] |

窦森, 白洪波, 林长年, 等.秸秆深埋还田覆土施肥联合作业机(实用新型, ZL 201620102002. 6). 2016-06-22 Dou S, Bai H B, Lin C N, et al. Straw deep-buried into field and fertilizer joint operation machine(Utility model patents, ZL 201620102002. 6). 2016-06-22 (  0) 0) |

| [7] |

窦森, 王瑞丽, 白洪波, 等.一种聚翻组合式秸秆深还机(发明专利, ZL 201610359059. 9). 2017-08-04 Dou S, Wang R L, Bai H B, et al. A kind of machine with multi-gathering straw and deep incorporation to subsoil(Patent, ZL 201610359059. 9). 2017-08-04 (  0) 0) |

| [8] |

窦森, 李凯, 杨轶囡, 等.一种风力注入秸秆深还筒式犁(发明专利, ZL 201610418091. X). 2019-01-04 Dou S, Li K, Yang Y N, et al. A kind of tube plow injecting straw to subsoil with wind power(Patent, ZL 201610418091. X). 2019-01-04 (  0) 0) |

| [9] |

王瑞丽, 杨鹏, Jahun R F, 等. 秸秆深埋还田开沟灭茬机设计与试验. 农业工程学报, 2017, 33(5): 40-47. Wang R L, Yang P, Rabiu F J, et al. Design and experiment of combine machine for deep furrowing, stubble chopping, returning and burying of chopped straw (In Chinese). Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(5): 40-47. (  0) 0) |

| [10] |

李长龙.翻埋条件下玉米秸秆分解速率及其对土壤有机碳含量的影响.长春: 吉林农业大学, 2015 Li C L. Straw decomposition rate under the condition of burying corn stalks and its effect on soil organic carbon(In Chinese). Changchun: Jilin Agricultural University, 2015 http://cdmd.cnki.com.cn/Article/CDMD-10193-1015963702.htm (  0) 0) |

| [11] |

张华亮, 关松, 窦森. 秸秆深还对黑土团聚体特征比值的影响. 吉林农业, 2015(12): 56. Zhang H L, Guan S, Dou S. Effect of corn stover deep incorporation on the ratio of characteristics of aggregates of black soil (In Chinese). Jilin Agriculture, 2015(12): 56. (  0) 0) |

| [12] |

谭岑, 窦森, 靳亚双, 等. 秸秆深还对黑土耕层根区养分空间分布的影响. 吉林农业大学学报, 2018, 40(5): 603-609. Tan C, Dou S, Jin Y S, et al. Effectsof corn overcast deep incorporation on spatial distribution of nutrients in root zone of black soil (In Chinese). Journal of Jilin Agricultural University, 2018, 40(5): 603-609. (  0) 0) |

| [13] |

扶明英.秸秆集中深埋对土壤养分淋失及作物生长的影响.南京: 南京农业大学, 2012 Fu M Y. Effects of straw deep-buried on soil nutrient leaching and crop growth(In Chinese). Nanjing: Nanjing Agricultural University, 2012 http://cdmd.cnki.com.cn/Article/CDMD-10307-1013284399.htm (  0) 0) |

| [14] |

翟利民.秸秆深施还田蓄水效应与秸秆深施机性能的试验研究.哈尔滨: 东北农业大学, 2012 Zhai L M. Experimental study on the impoundment effects of straw deep application and the properties of straw deep application machine(In Chinese). Harbin: Northeast Agricultural University, 2012 http://cdmd.cnki.com.cn/Article/CDMD-10224-1012515194.htm (  0) 0) |

| [15] |

张帅, 孔德刚, 常晓慧, 等. 秸秆深施对土壤蓄水能力的影响. 东北农业大学学报, 2010, 41(6): 127-129. Zhang S, Kong D G, Chang X H, et al. Effect of straw deep application on soil water storage capacity (In Chinese). Journal of Northeast Agricultural University, 2010, 41(6): 127-129. DOI:10.3969/j.issn.1005-9369.2010.06.025 (  0) 0) |

| [16] |

邱立春, 孙跃龙, 王瑞丽, 等. 秸秆深还对土壤水分转移及产量的影响. 玉米科学, 2015, 23(6): 84-91. Qiu L C, Sun Y L, Wang R L, et al. Influence of deep-buried maize stalks on soil moisture transfer and maize yield (In Chinese). Journal of Maize Sciences, 2015, 23(6): 84-91. (  0) 0) |

| [17] |

王喜艳, 窦森, 张恒明, 等. 玉米秸秆持水深埋对辽西瘠薄耕地土壤养分及玉米产量的影响. 西北农业学报, 2014, 23(5): 76-81. Wang X Y, Dou S, Zhang H M, et al. Effect of waterlogged maize stalk deep returning on soil nutrients and maize yields of barren farmland in west Liaoning Province (In Chinese). Acta Agriculturae Boreali-Occidentalis Sinica, 2014, 23(5): 76-81. (  0) 0) |

| [18] |

朱姝, 窦森, 关松, 等. 秸秆深还对土壤团聚体中胡敏素结构特征的影响. 土壤学报, 2016, 53(1): 127-136. Zhu S, Dou S, Guan S, et al. Effect of corn stover deep incorporation on composition of humin in soil aggregates (In Chinese). Acta Pedologica Sinica, 2016, 53(1): 127-136. (  0) 0) |

| [19] |

朱姝, 窦森, 陈丽珍. 秸秆深还对土壤团聚体中胡敏酸结构特征的影响. 土壤学报, 2015, 52(4): 35-46. Zhu S, Dou S, Chen L Z. Effect of deep application of straw on composition of humic acid in soil aggregates (In Chinese). Acta Pedologica Sinica, 2015, 52(4): 35-46. (  0) 0) |

| [20] |

董珊珊, 窦森, 李立波, 等. 秸秆深还不同年限对黑土腐殖质组成和胡敏酸结构特征的影响. 土壤学报, 2017, 54(1): 151-159. Dong S S, Dou S, Li L B, et al. Effect of corn stover deep incorporation with different years on composition of soil humus and structural characteristics of humic acid in black soil (In Chinese). Acta Pedologica Sinica, 2017, 54(1): 151-159. (  0) 0) |

| [21] |

窦森, 关松, 杨轶囡, 等.玉米秸秆机械化富集深埋还田技术规范.吉林省地方标准. 2018, 12 Dou S, Guan S, Yang, Y N. Technical specification for mechanized enrichment and deep burial of corn straw, Local Standard of Jilin Province. 2018, 12 (  0) 0) |

2019, Vol. 56

2019, Vol. 56